Nirzar's blog

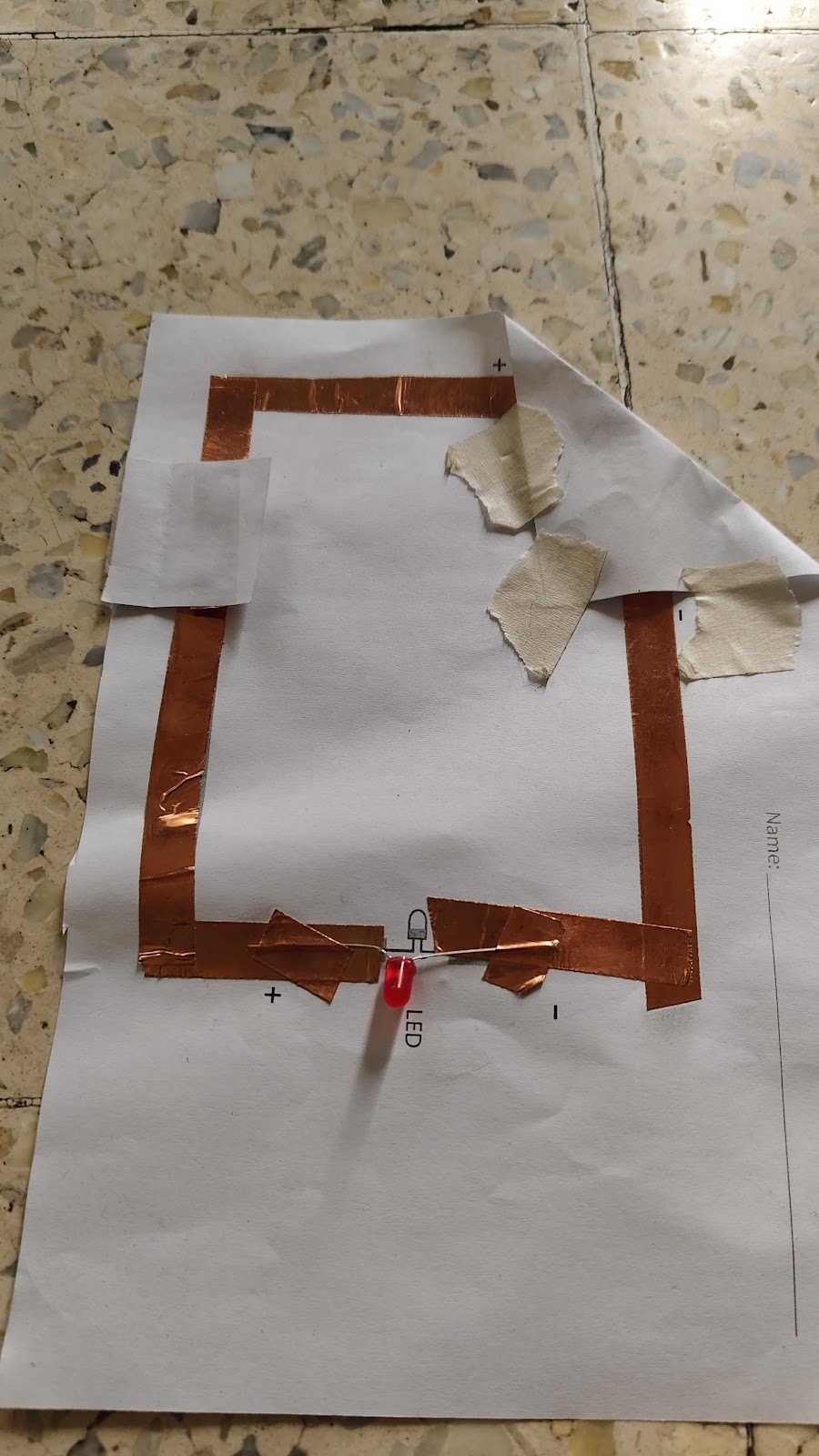

Simple Circuit

Components:

Copper tape

LED

Coin cell battery (3V)

Steps:

Create a rectangle using copper tape.

Attach the LED to the copper tape, ensuring the longer leg (anode) is connected to the positive side and the shorter leg (cathode) to the negative side.

Place the coin cell battery in one corner with the negative side facing down.

Result:

The LED glows.

Warning - In the simulation, the current is 61.9 mA, which exceeds the recommended maximum of 20 mA for LEDs. This can damage the LED.

Solution:

Add a resistor in series with the LED to limit the current flowing through it. Using Ohm's Law:

For a 3V battery and a target current of 20 mA:

.

Use a 150 Ω resistor to protect the LED.

Series Circuit

Components:

Copper tape

2 LEDs

Coin cell batteries

Steps:

Connect the copper tape in a rectangle.

Attach 2 LEDs in a row (series) to the copper tape.

Ensure the positive leg of the first LED is connected to the battery's positive side, and the negative leg of the second LED is connected to the battery's negative side.

Result:

Both LEDs glow, but they are dimmer than in the simple circuit. (They glow properly with 2 coin cell batteries.

The voltage is shared between the LEDs (1.5V each for a 3V battery).

The current remains the same (20 mA with a resistor).

Parallel Circuit

Components:

Copper tape

2 LEDs

Coin cell battery

Steps:

Connect the copper tape in a rectangle.

Attach two LEDs side by side (in parallel) to the copper tape.

Ensure both LEDs are connected directly to the battery's positive and negative sides.

Result:

Both LEDs glow brightly.

The voltage across each LED is the same (3V), but the current is split between them.

In the simulation, the current is 38.9 mA, which exceeds the recommended maximum.

Solution:

Add resistors in series with each LED to limit the current flowing through them. Use a 150 Ω resistor for each LED.

Breadboard Connections

Description:

The breadboard has two sets of vertical power rails (positive and negative) on the sides.

The main grid is horizontally connected in rows, separated by a central partition.

To connect components:

Place the battery's positive terminal to the positive rail and the negative terminal to the negative rail.

Use jumper wires to connect components horizontally across the rows.

Example:

Connect the LED's anode (longer leg) to a resistor, then to the positive rail.

Connect the LED's cathode (shorter leg) to the negative rail.

RC Robot

Components:

Copper tape

9V battery

Copper wires

Foam sheet

Printouts

Soldering iron

100 RPM motors

Steps:

Stick the printouts onto the foam sheet to create the robot's body.

Solder wires to the copper tape for electrical connections.

Solder all intersection points on the copper tape to ensure connectivity.

Stick copper tape onto the template to create the circuit.

Connect the motors to the copper tape and power them with the 9V battery.

Working:

Power Supply:

The 9V battery supplies power to the entire system. When the circuit is complete, electricity flows through the copper tape and wires to the motors and the remote control.

Remote Control Operation:

The remote control has buttons that correspond to different movements (e.g., forward, left, right).

When a switch is pressed, it completes a specific circuit, sending a signal to the robot.

Motor Activation:

The signal from the remote control activates the 100 RPM motors.

Movement:

The 100 RPM motors provide the necessary speed to move the robot. The foam sheet supports the motors and other components.

The robot moves according to the signals received from the remote control.

Stopping:

When no buttons are pressed, the circuit is incomplete, and the motors stop rotating. This brings the robot to a stop.

LDR, LED, and Transistor Circuit

Description:

This circuit utilizes a Light-Dependent Resistor (LDR) to control an LED assisted by a transistor. When light falls on the LDR, its resistance decreases, allowing current to flow through the transistor and turn on the LED.

Working of electric components

LED (Light Emitting Diode):

An LED is a tiny light that glows when electricity passes through it.

It only works when connected the right way (positive to positive, negative to negative).

LDR (Light Dependent Resistor):

An LDR is a special resistor that changes its resistance in response to light.

In bright light, its resistance is low (lets more electricity flow).

In darkness, its resistance is high (lets less electricity flow).

Battery:

The battery provides the power (electricity) needed to make the LED glow.

It has a positive (+) and negative (-) side.

Resistor:

A resistor limits the flow of electricity to protect the LED from getting too much power and burning out.

colour codes of resistors-

- Colour code - Red, Grey, Blue, Red, Brown

- Red = 2, Grey = 8, Blue = 6

Calculation-

(Convert into kilo-ohm)

1% tolerance of 28.6 kOhm = 0.286

Solar panel circuit for solar desk lamp

The following components are required for making the above circuit:

Solar Panel

Battery

LED

2-Way Switch

Transistor

LDR (Light Dependent Resistor)

Resistor

Diode

Connections:

The positive terminal of the battery and the positive terminal of the solar panel are connected to the common terminal of the 2-way switch.

Terminal two of the switch is connected to the anode of the LED.

The anode of the LED is connected to the resistor, the first terminal of the LDR, and the base of the transistor.

The negative terminal of the battery is connected to the negative terminal of the solar panel, which is further connected to the diode, the second terminal of the LDR, and the emitter of the transistor.

The cathode of the resistor is connected to the collector of the transistor.

3D Designing:

3D designing involves creating a digital model of the circuit enclosure or any other component using CAD (Computer-Aided Design) software.

The design can be optimized for 3D printing by ensuring proper wall thickness, minimal overhangs, and support structures where necessary. The model should be exported in a compatible file format for 3D printing.

3D Printing:

Model: Flash Forge Adventurer Pro

Materials: PLA, ABS

Nozzle Temperature for PLA: 210°C

Bed Temperature for PLA: 50°C

Nozzle Temperature for ABS: 230–250°C

Bed Temperature for ABS: 90–110°C

1. Importing the 3D Model

The process begins by importing a 3D model into Orca Slicer. The model can be created using CAD software or downloaded from online repositories.

2. Model Preparation

Scale: Adjust the model's size to suit your needs.

Rotate: Change the orientation of the model to optimize print quality or reduce supports.

Cut: Split large models into smaller, printable parts.

3. Slicing the Model

After configuring the settings, Orca Slicer processes the 3D model and divides it into layers. Each layer is represented as a set of instructions that the printer follows to create the object.

The software uses advanced algorithms to:

Optimize toolpaths for efficiency and quality.

Generate support structures where needed.

Calculate filament extrusion rates and retraction settings to prevent stringing.

4. Exporting G-code

Once the slicing process is complete, Orca Slicer exports the G-code file. This file contains all the instructions the printer needs to create the physical object.

The G-code can be saved to an SD card, USB drive, or sent directly to the printer via a connected computer or network.

Fish programs

Wires

The battery's positive is connected to the first column on the breadboard, and the negative is connected to the second column. LED's positive is connected to the first column, and its negative is connected to row 20 of the breadboard. Buzzer's positive is also connected to the first column, and the negative is connected to row 20. The IR sensor module VCC is connected to the first column, GND is connected to the second column, and DO is connected to row 20 of the breadboard

Project.4: Automatic plant watering alarm

composter

working

- Add a culture packet, which is a combination of beneficial bacteria and fungi

- Introduce kitchen waste

- Rotate 5 times clockwise and 5 times anti clockwise

.jpg)

.jpg)

.jpg)

Comments

Post a Comment